When conducting an analysis of costs for a given plant, its modernisation or expansion, it is also worth assessing the condition of its systems. Factors such as electrical system and power system load, compressor, ventilation, and air conditioning utilisation levels, and the condition of transformers, play a major role in balancing production costs and business costs. If you are analysing your costs and looking for savings within the process, or if you are considering purchasing machines and expanding the plant, you first need to check whether your existing infrastructure meets the essential requirements.

A plant audit that will give you the exact answer to the question of what losses there are or how big potential there is to be tapped is a useful tool.

One very important factor affecting production efficiency is the correct selection and optimal use of devices. Remember that increasing efficiency does not have to involve investments in new devices. Sometimes it turns out that after conducting an audit and basic measurements, system optimisation and change of parameters are alone enough to generate the expected savings or increased efficiency.

We perform audits of existing plants and systems, as well as analyses of investments planned or in design. We’ll show you the best solutions, possible savings and the way to optimise your costs.

Audits

- Audit of power supply costs at the facility/plant, including tariff assessment, rated power, and electrical, thermal and gas reactive power management.

- Audit of feasible alternative power supply, including renewable energy sources (RES), green certificates and reductions in/exemptions from power charges for businesses.

- Audit of energy-related risks at the facility/plant.

- Audit of energy optimisation at the facility/plant (more for less).

- Audit of energy efficiency at the facility/plant for the purposes of the Energy Regulatory Office (URE) (for more than 250 employees or 50 million EUR annual turnover).

- Monitoring the quality and continuity of power supply and inspection of the metering system.

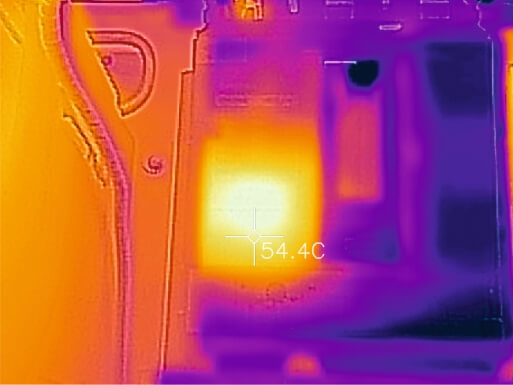

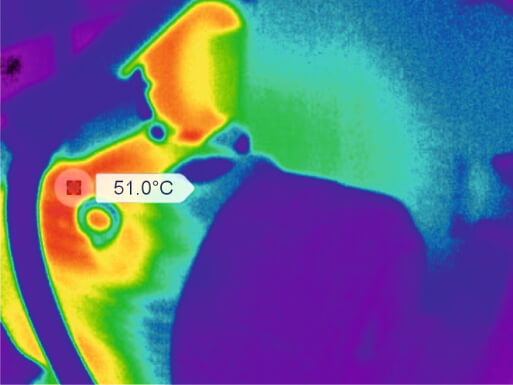

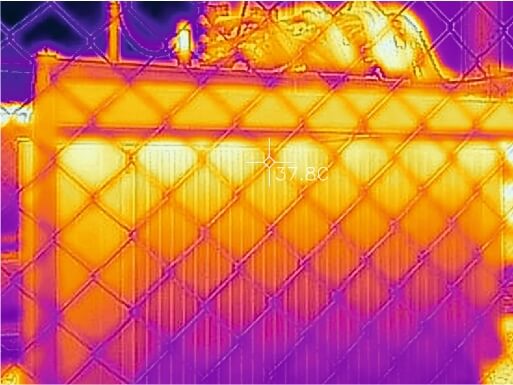

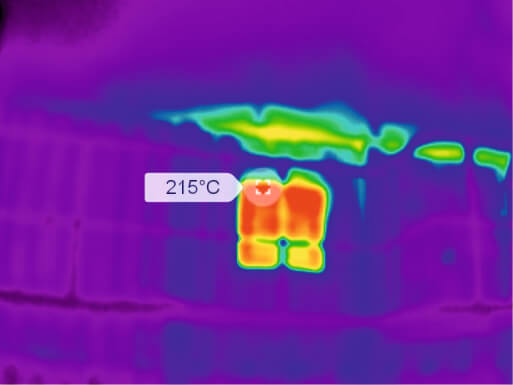

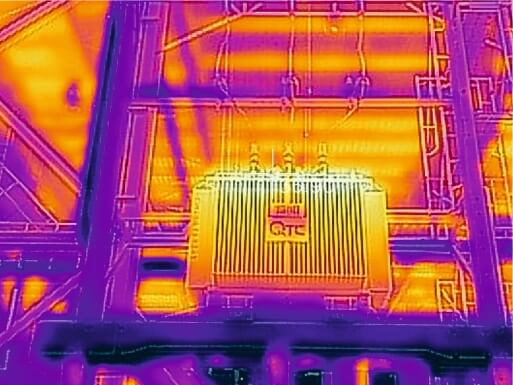

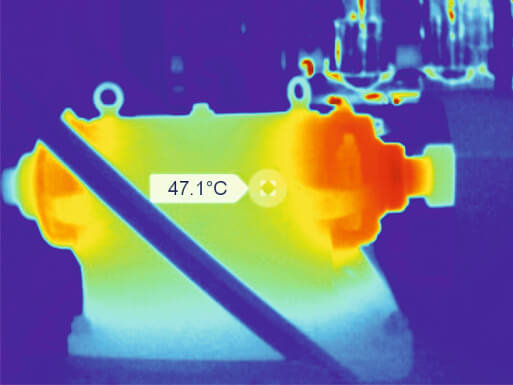

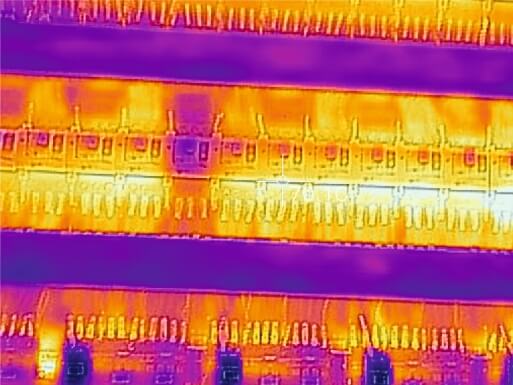

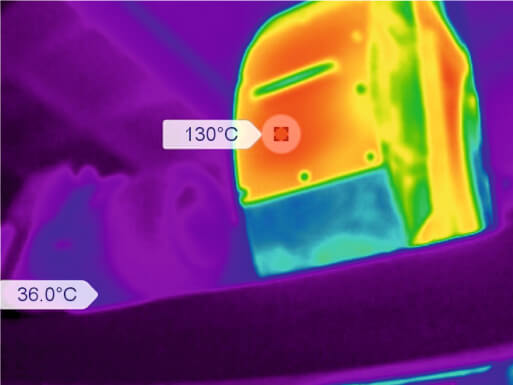

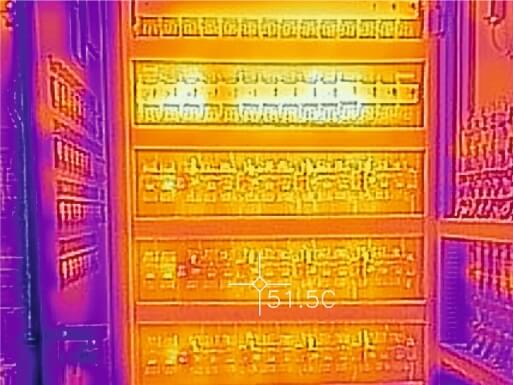

- System quality check and energy loss and leakage detection.

- Configuration/check of the correct reactive power adjustment at the facility/plant.

- Fire safety check of the system and buildings.

- Electric shock safety inspection.

- Inspection of the quality of lighting at workstations – parameter monitored by the National Labour Inspectorate (PIP).

Inspections, measurements and functional testing of HV, MV and LV electrical facilities:

- Inspections of live systems.

- Inspections and measurements of transformers, power lines and switchgear.

- Measurements and functional testing of HV, MV and LV protections.

- Testing and checks of auxiliary systems.

- Inspections and measurements of battery capacity.

- Inspections and functional testing of rectifiers and power supply units.

- Inspections and measurements of power generators.

(heating and cooling)

Article 62 of the Building Law